At Ashok Long Life Tools Engineering, we are driven by a singular purpose — to engineer precision tooling solutions that power modern manufacturing. With decades of experience in broach and gauge manufacturing, we have established ourselves as a trusted partner for industries that demand accuracy, durability, and consistency without compromise.

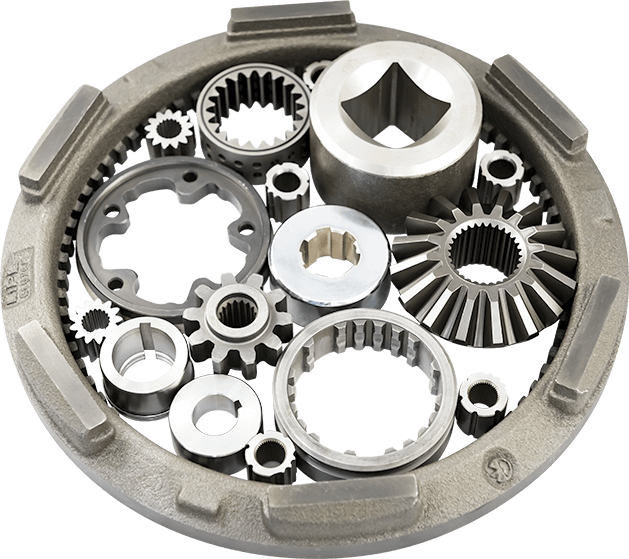

From involute and straight spline broaches to round, keyway, square, hex broaches and precision plug gauges, every tool we manufacture reflects our deep technical expertise and commitment to engineering excellence.

Over the years, we have successfully manufactured and supplied tens of thousands of broaches—including involute spline, straight spline, keyway, round, square, hex, serration, and special-profile broaches—engineered for high accuracy and long service life across diverse applications.

Our strength lies in close collaboration with OEMs, Tier-1 suppliers, and precision manufacturers. By working alongside customer engineering teams, we deliver customized broaching solutions that improve productivity, reduce downtime, and ensure consistent quality.

From complex internal profiles to tight-tolerance applications, we have developed thousands of custom broaches and tooling solutions. Our design expertise enables us to solve challenging machining requirements with confidence and precision.

With more than two decades of hands-on manufacturing experience, we have built deep process knowledge in broaching, reconditioning, repair, contract broaching, and technical support—making us a complete solutions partner, not just a tool supplier.

Our strength lies in offering complete broaching solutions under one roof — from manufacturing and reconditioning to contract broaching, calibration, and technical support. With decades of hands-on experience, we help customers meet evolving production demands with confidence and consistency.

We manufacture high-quality broaches for involute spline, straight spline, keyway, round, square, hex, serration, and special profiles—engineered for long tool life, tight tolerances, and consistent production performance.

Our re-sharpening, repair, and reconditioning services restore original tool geometry and cutting performance, extending broach life and reducing tooling costs without compromising accuracy.

Every broach and service is validated through strict dimensional checks, profile inspection, and performance testing to guarantee accuracy, durability, and repeatability.